LOCATION STRATEGY

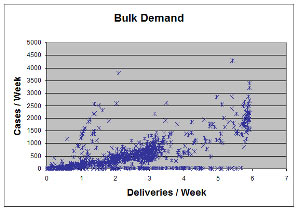

Typical Drop Size & Frequency

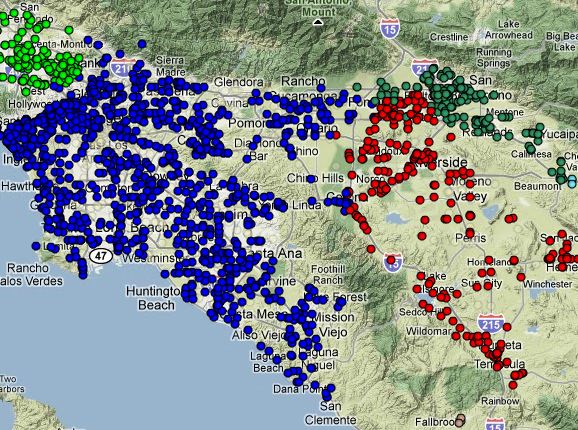

Route Planning Tools Cannot Determine Territory Boundaries

When DSD operations are growing, or companies merge, the complete cost analysis to decide where to locate consolidated warehouses, whether they should all hold inventory, and how to split the territories by truck type are much too complex to do with spreadsheets.

DSD experience and the right optimization tools are the keys to accurate Location Strategy analysis!

The most commonly used network tools must group customers in the same zip code and call them a route! This misrepresents the principles of modeling. The real world complexity of DSD delivery networks needs to be comprehended in the modeling tools, otherwise you aren’t representing your routes accurately for stem time, workday, stop count, etc…What makes it so complex?

- Visit frequency, drop size, and trailer types all vary by individual customer.

- The cost drivers of a DSD network are heaviliy influenced by the multi-stop nature of the routes.

- Cross dock and drop lot options often drive large cost savings but it is hard to comprehend their work day and drive time impact.

Sometimes driving more miles from fewer warehouses makes sense. Fewer warehouses are easier to manage, require less safety stock, and with enough volume from consolidation, may support automation. Adding crossdocks and drop lots to your network may enhance your operating savings, and can be studied with the location strategy tools.