ROUTE OPTIMIZATION

Detailed Stop Plans By Route

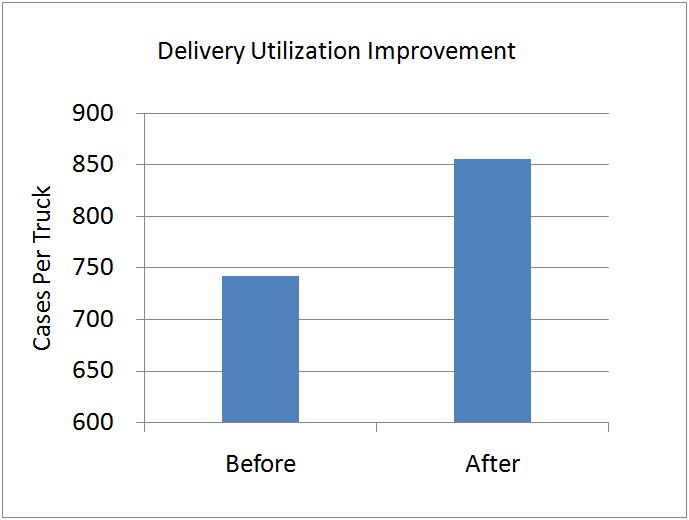

Route Optimization Improves Utilization

The fixed costs of a route vary based on region and equipment type from $70,000 to $120,000 annually. Yet reroute tools emphasize reducing miles over reducing routes! Not comprehending how to use these tools in a core process is reducing route utilization every day, and costing delivery operations a lot of money.

Historically, route planning is a painful process. No one likes the fact that you’re chaning service days and possibly drivers, and service may suffer. Most route planning is done because it’s been a year or two since the last reroute or enough changes have occured that we’re willing to suffer through the process.

We task sales with stop and route reduction targets and wait for their inputs. Then the route planner is told to make it all fit usually with little change to workday, channel mix, or trailer type. What results are more stops for some routes and typically limited reduction in miles.

Setting up a scenario based reroute process will improve utilization and cost savings vs. a traditional process!

We utilize scenario based route planning process that tasks both the sales team and the route planner with getting out of the box and identifying ways to meet your service goals with better route utilization.If you set up scenario based route planning as a Core Process you should expect the following:

- Reduced sales & delivery route count

- Improved delivery utilization

- Balanced daily demand and delivery capacity

- Reduced compliance issues including hot shots and cancellations

For more information download our white paper on the subject: Eight Items Typically Missed in DSD Reroute