OPERATIONS MASTER PLANNING

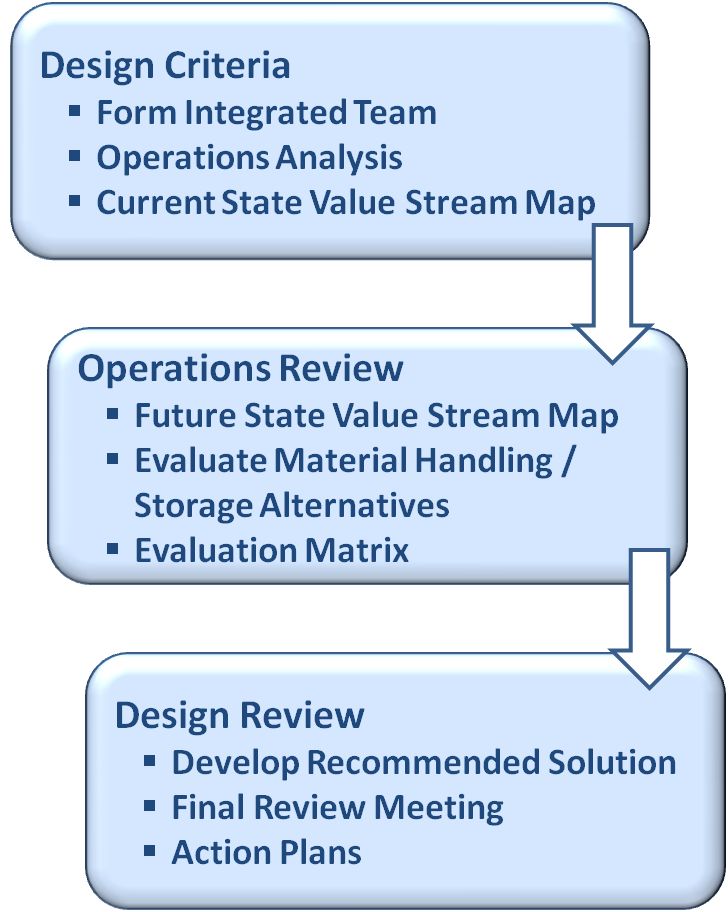

Operations Master Planning Process

US manufacturers are making great strides applying waste elimination methodologies like 5S and kaizen improvement to production processes. Even though pull production systems like kanbans are being used well, we often see the pull production system disconnected from the push planning of the ERP planning systems used for component and supplier planning. The lack of synchronization is covered up with inventory and lots of planners and coordinators.

By fixing the planning steps from suppliers to customers, excess inventory is eliminated and lead-times will shrink

The net result of keeping push planning and pull production is waste; causing overproduction, excess inventory and unnecessary material movement.- Are you overproducing just to drive standard cost absorption?

- Do you have off site warehouses with inventory or excess inventory?

Once the coupling of pull planning and pull production is accomplished the next step is to manage all planning processes with a robust Sales & Operations Planning process to anticipate demand trends and allow your leadership team to drive the competitive advantage that lean operations provide you.